Description

Product Details: |

|||

| Products Type: | Aluminum composite panel | Material: | Alloy AA1001 3003 5005 |

| Sample: | Samples Free | Delivery Time: | 7-15-30 days depends on quantity |

| Type/Surface: | Roller coating (surface coating can make according to customer’s requirements) | ||

| Panel thickness : | 0.08mm,0.1mm,0.15mm,0.2mm,0.3mm,0.4mm,0.5mm or customized Color RAL/PANTONG or as our own color chart or customized | ||

| Advantage: | Environment friendly-no wasteful of material,good rigidity-premium reinforcement properties,Good resistance to corrosion.Certificates: CE, ISO, SGS | ||

Payment and shipping terms: |

|||

| Minimum order quantity: | 200 square meters | Supply capacity: | 30,000 square meters |

| Delivery time: | 15-30 days | Price: | USD 15-50/square meter |

| Packaging details: | Export Packaging, Protective Film, Bubble Film, Wooden Frame/Iron Frame | ||

| *Special dimension and designs can be ordered according to the enquiry of designers, architects and consultants | |||

Aluminum Composite Panel(ACP)

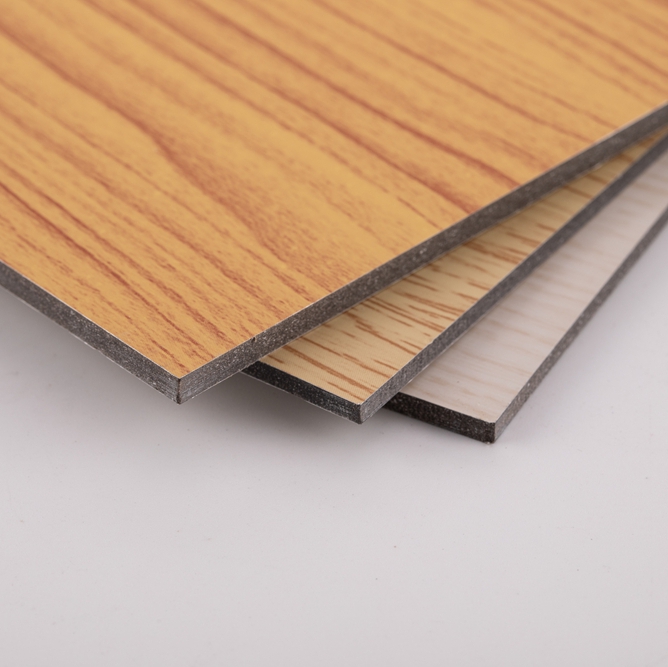

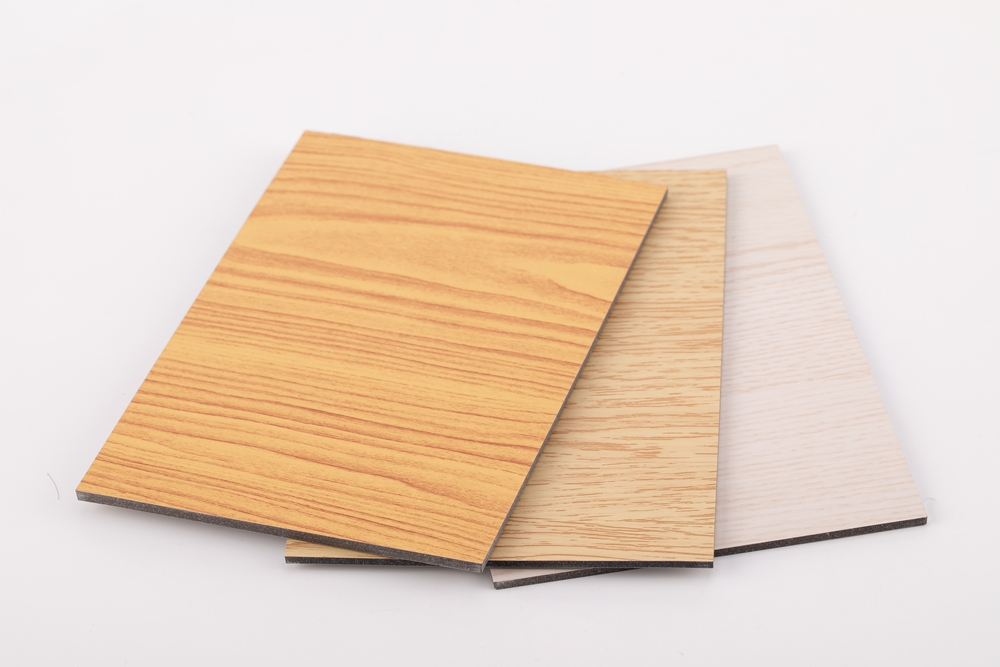

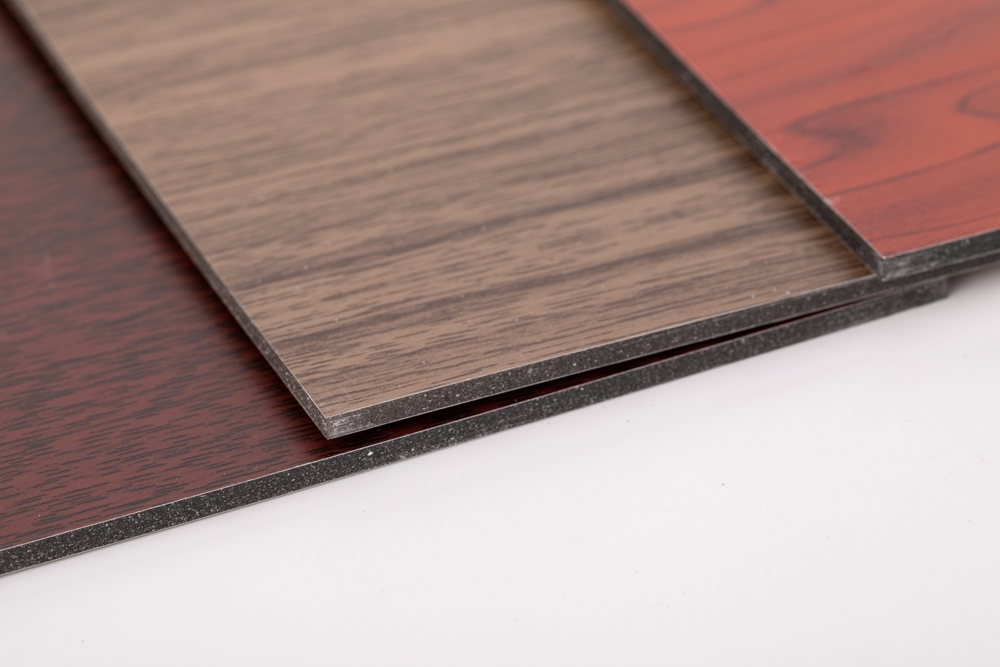

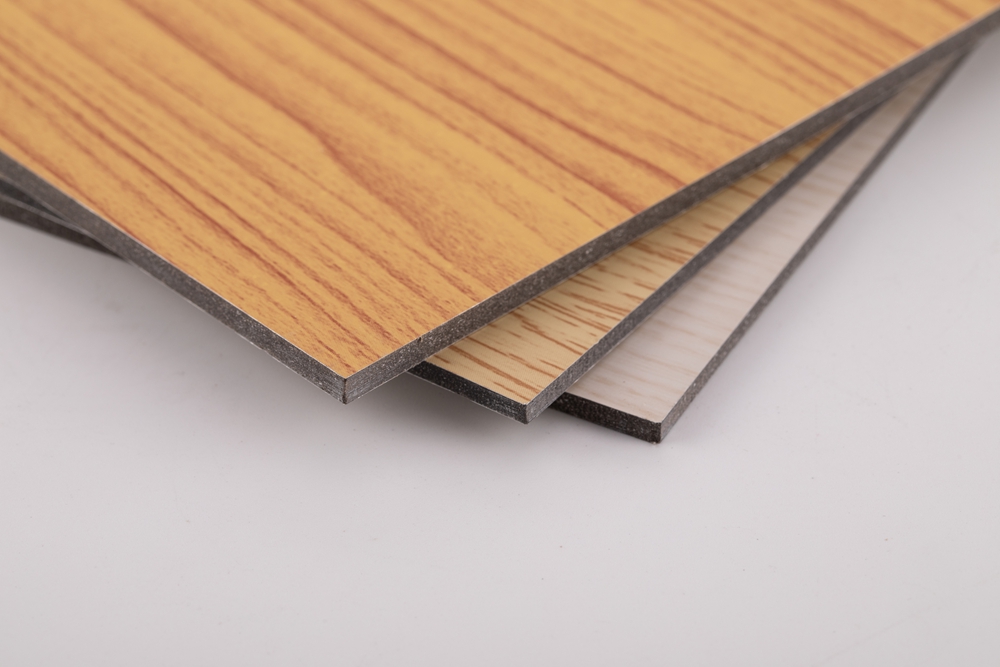

Wood grain color

Imitation stone color

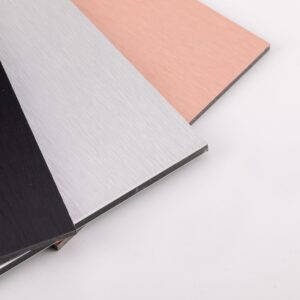

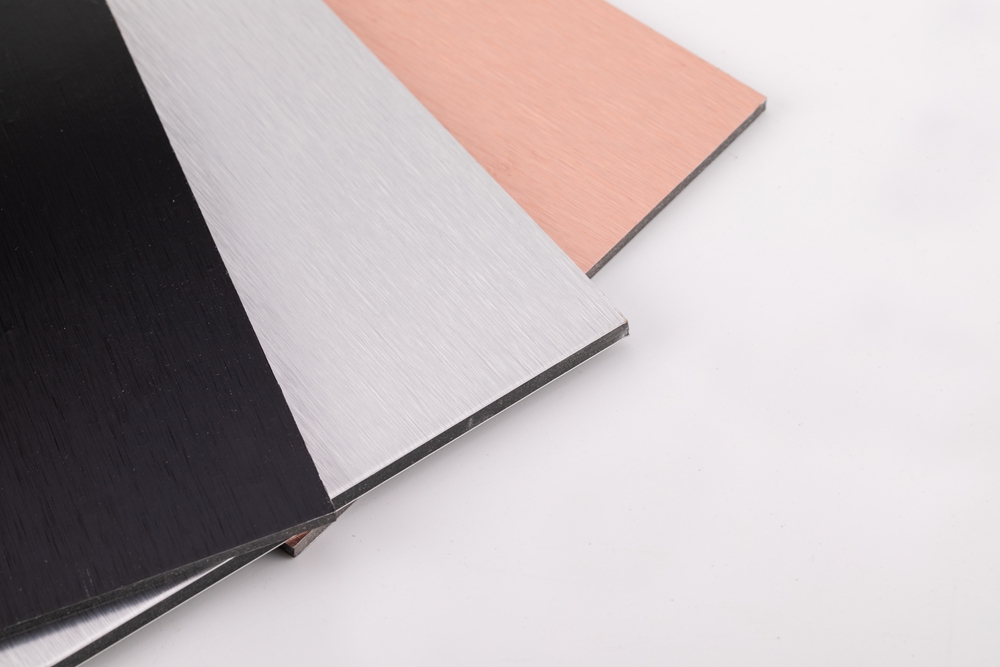

Brushed effect

Application Scope of Alucobond panel

-

- Building exterior curtain walls, such as airports, hospitals and research centers

- Decoration reformation storey-addition for old buildings and movable houses

- Decoration of interior walls, ceilings, bathrooms, kitchens and balconies

- Shop’s door decoration

- Advertisement boards, display platforms and signboards, billboards, exhibition desks and notice boards

- Wallboards and ceilings for tunnel

- Industrial material, vehicle and boat materials

- hoarding

- Furniture

-

Other building board

Production workshop

At present, we have German LFK computer numerical control sheet metal equipment, as well as a number of computer numerical control plate shears, bending machines, engraving machines and Japanese AMADA computer numerical control punches.

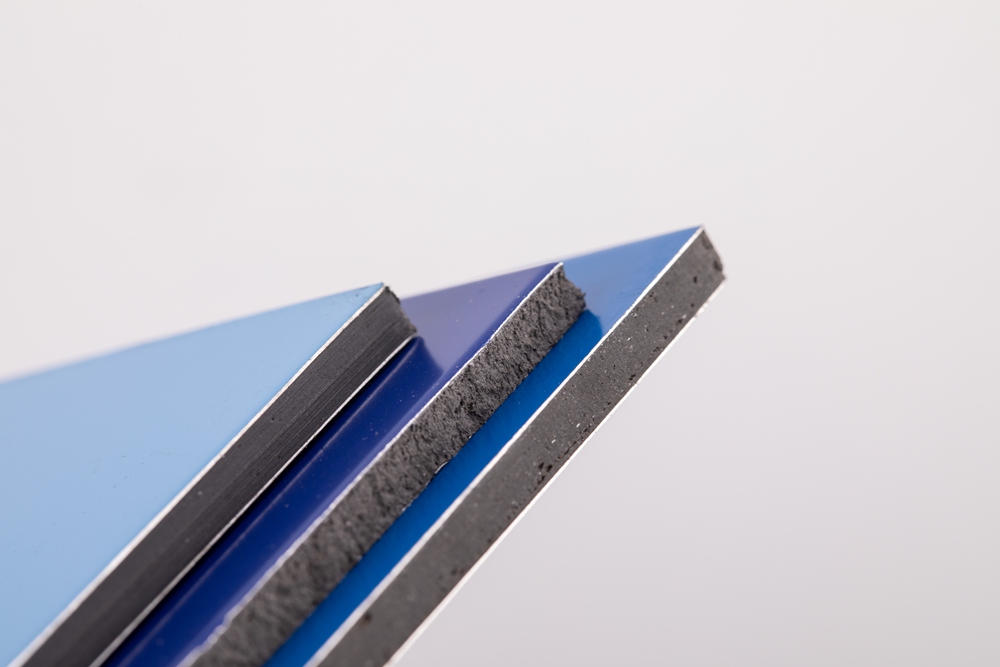

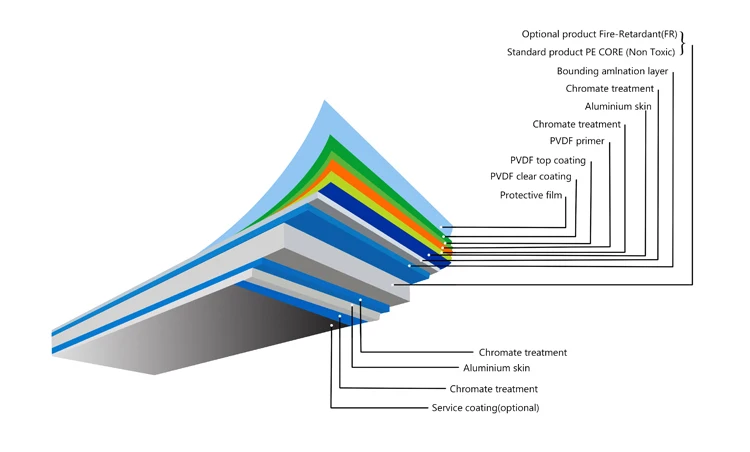

Schematic diagram of aluminum composite panel structure

Metallic Aluminum Composite Panel is produced by a continuous lamination process,

in which a sheet of the material that will make up the core is extruded

and compacted between two aluminium sheets that are unwound at the same time. Finally,

the flatness of the material is compacted and perfected and a protective film is applied.

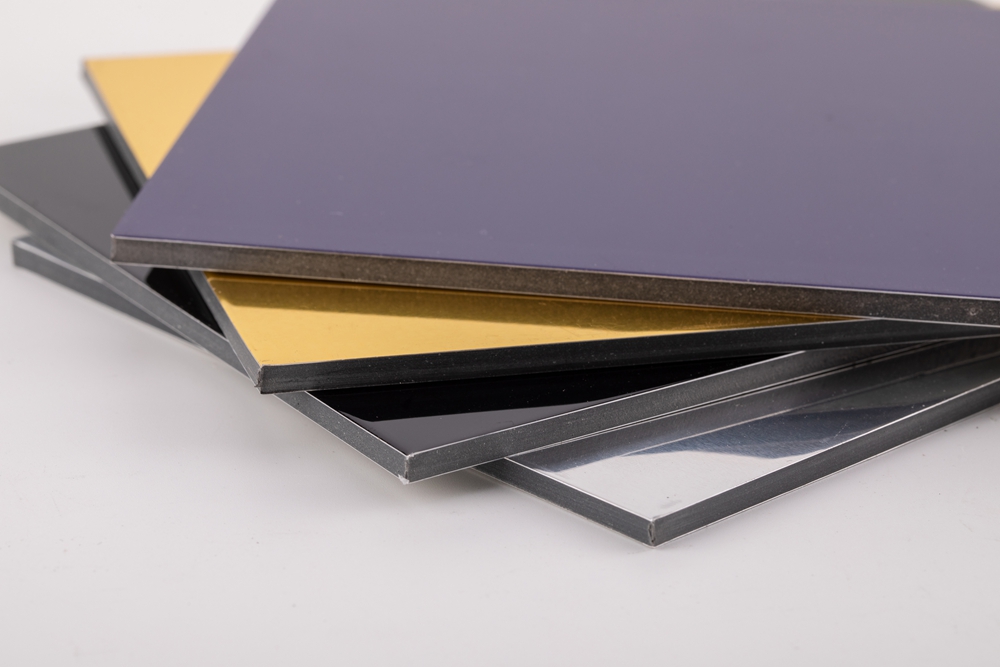

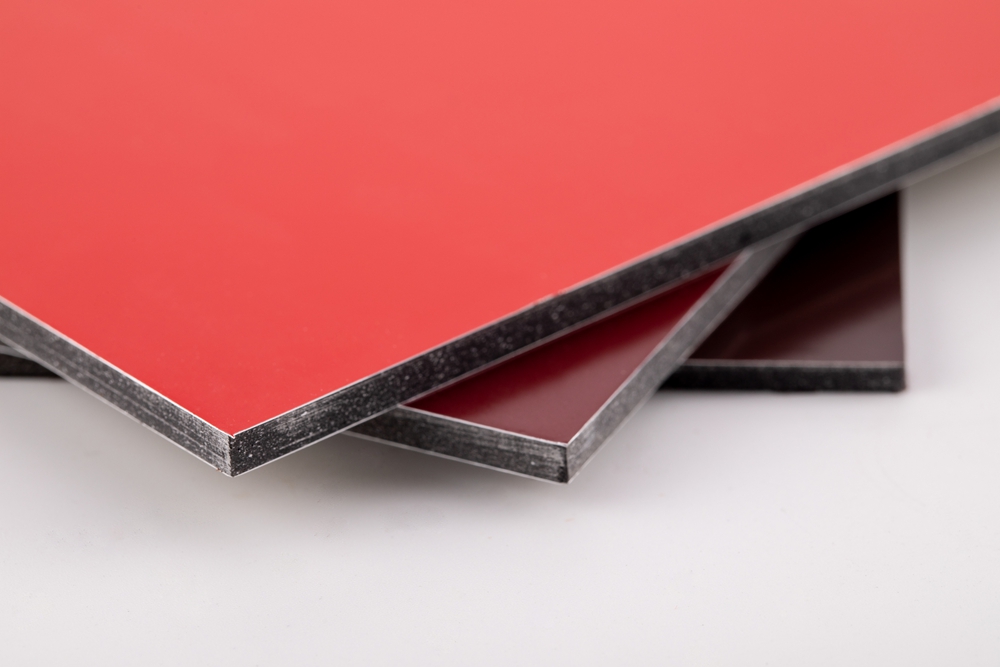

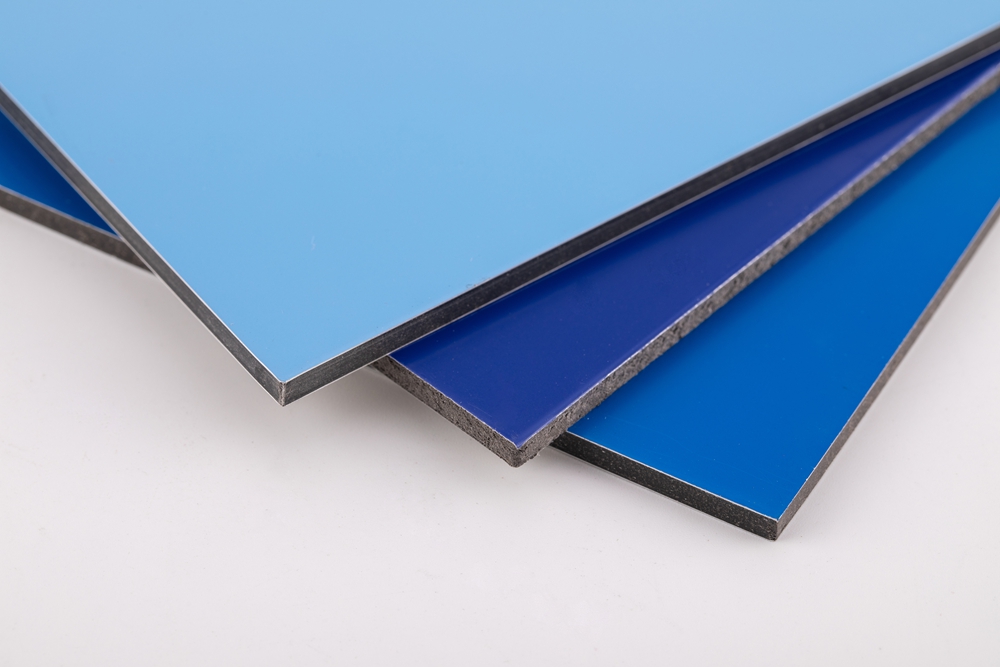

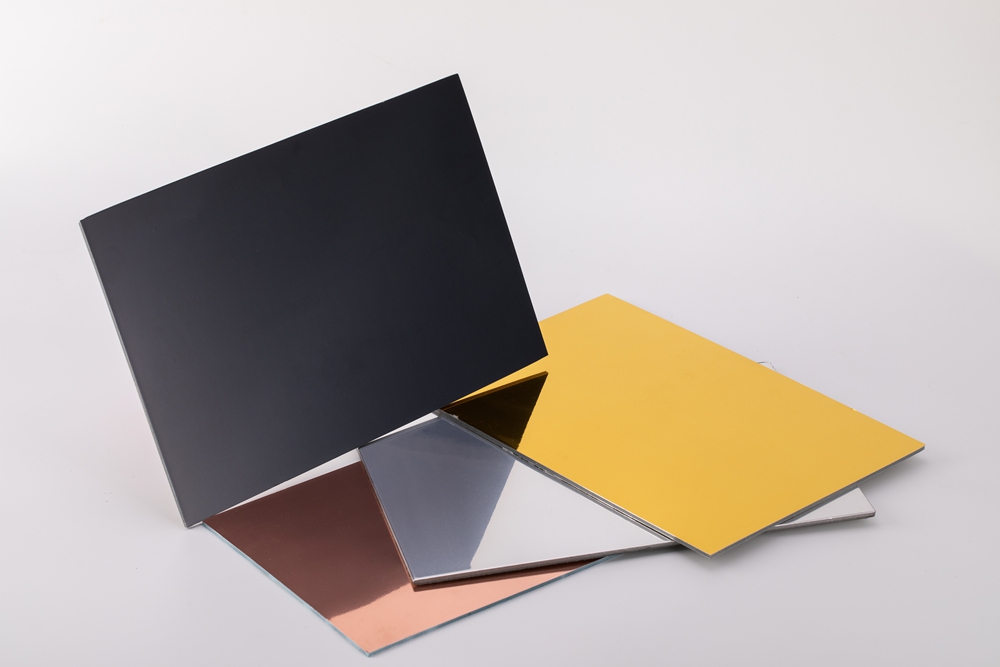

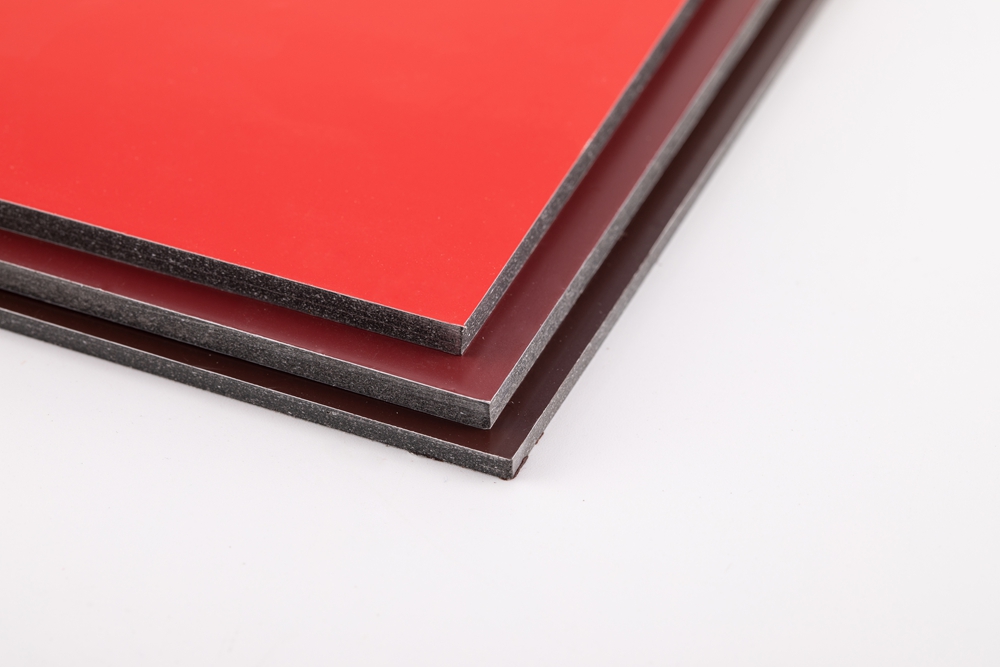

Spray color card

The aluminium composite panel allows a large number of different finishes.

In addition, it can be adapted to any colour from the RAL colour chart.

The solid finishes are homogeneous and hardly suffer the variation of their tonality with the incidence of light.

They provide a sensation of solidity to the facade and are easily combined with other finishes.

Solid color chart in the following. If you want other color,

please kindly feel free to contact us.We accept custom colors.

Advantages

There is one thing we can all agree on within the construction industry,

and it is that the popularity of aluminum composite panel has not stopped growing over the past few years.

Its use has been expanding under the cover of energy efficiency, low price and construction possibilities.

This type of material is specially designed for the construction of ventilated facades,

their renovation or rehabilitation. It provides solutions that can be adapted to all fields of architecture.

Aluminum composite panel product to installation

As a professional manufacturer, Lecton Aluminum has an excellent design team and manufacturing workers as well as advanced CNC equipment. We can produce according to the customer’s building area, required ceiling tile size, specification, pattern, color and competitive budget requirements. .

All aluminum ceilings are prefabricated according to customers’ designs and drawings, you just need to make a frame and prepare some bolts to install.

Common Problem

FAQ

1: Are you trading company or factory?

We are 100% professional manufacturer, more than 50 producing machines, with more than 100 staffs.

2: Can you accept our own designs?

Yes. Size, color, patterns/designs can be customized as per your project requirements.

3: What is your MOQ order?

We accept small order also, MOQ is 100sq.m

4: what is the delivery time?

It will be finished within 30days after received the deposit.

Please contact me for more details

Whatsapp:+86 158 9966 6189

Email: [email protected]